Novelties 2024

Towards digitalisation with barcode

A path to transformation for jewellers and goldsmiths

Birkenfeld, 11.11.2024. The state declares digitalisation to be the new paradigm of the economy and demands commitment across all sectors. As a first step for jewellers and goldsmiths, eXtra4 Software+Service recommends coded labels to digitise everyday processes using a scanner. The software company from Birkenfeld near Pforzheim demonstrates how easy it is for even smaller companies to generate benefits in their own operations for the jewellery and watch industry.

Digitalisation - a definition with practical relevance

Digitalisation is as complex as it is difficult to grasp. The German Federal Ministry for Economic Affairs defines digitalisation as ‘the use of data and algorithmic systems for new and improved processes, products and business models.’ For eXtra4, this generally means: the conversion of analogue processes, i.e. things that are done by hand, into processes that the computer can handle better digitally with the right software because it is faster, more accurate and more reliable than a human being. Translated in this way, it is easier to derive practical actions for everyday life .

The warehouse as a sensible starting point for digitalisation

One of the time-consuming routines that require constant attention from jewellers and goldsmiths is stock control. It is closely related to the item labelling. Only goods that are correctly identified can be correctly booked in the stockroom. Digitalisation in this area promises a high degree of time savings while at the same time improving precision in the warehouse and in associated processes at the checkout and in purchasing.

Key factor Item number

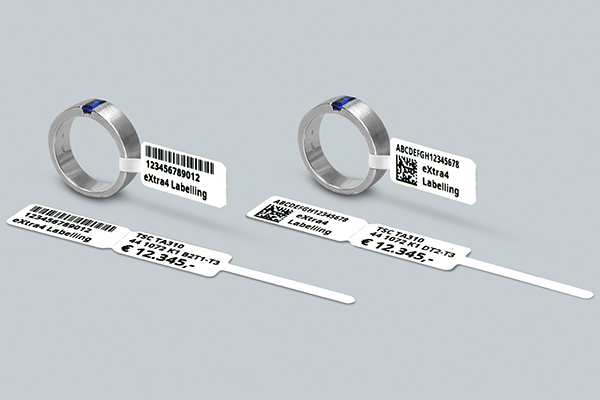

A unique item number makes goods unambiguously identifiable. It is the central component of precise item and stock management. All further information on an item, such as price, quality details and stock, is organised via the item number. As a kind of key, it grants access to this master data. The data itself can be saved in a list, in a table, even from a spreadsheet such as ‘Excel’, or in a database where all the details for an item are grouped in a data record. The machine-readable form of the item number is the code. This can be a barcode, which is a one-dimensional code consisting of black bars of different thicknesses and their spacing in different widths. Alternatively, a matrix code is also possible, a two-dimensional code that forms a rectangle from black and white pixel squares, widely used in its form as a QR code. Suitable software, such as eXtra4-win for labelling, converts the numerical sequence of the item number into the desired code .

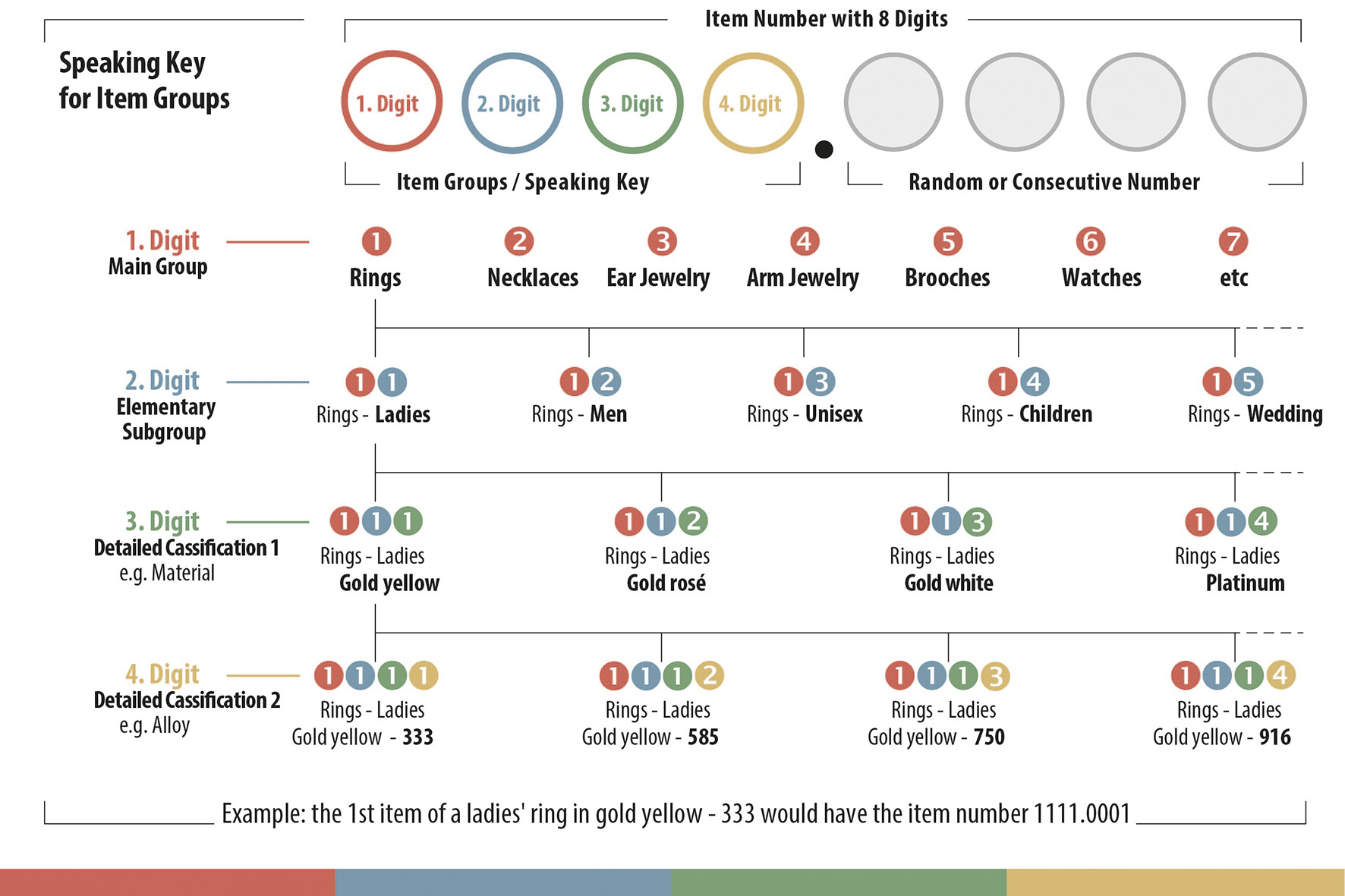

Structure of an item number

As a core component of stock management, the item number should be easy to handle. It must not be too long and complex for this. In eXtra4 practice, a number sequence with eight digits has proven its worth. Instead of assigning the item number completely randomly, it is advisable to develop a speaking key based on a categorisation of the stock of goods into item groups. With an 8-digit item number, the first four digits of the number sequence can be used for the item group and the following four for a consecutive or random number, i.e. for up to 10,000 items per item group. The advantage: experienced sales staff can reliably locate and correctly categorise an item using the four leading digits, which represent the system of item groups. In addition, items of the same type are displayed one below the other when listed by item number, which makes it easier to keep track of the . ...

More details on the software eXtra4-win

50 years of barcode –

successor already at the start

eXtra4 Labelling Systems with trend analysis for the industry

Birkenfeld, 22.08.2024. Premiere at the supermarket checkout: a barcode is scanned for the first time in the USA on 26 June 1974 - for a packet of chewing gum. 50 years later, barcodes are the standard for product marking and are also widely used for jewellery, watches and gemstones. Specialising in identification technology in this sector, Ferdinand Eisele observes new developments and can identify trends with his brand ‘eXtra4 Labelling Systems’. After all, coding is an important factor in digitisation.

35 years of barcode practice

Barcode technology has been part of the repertoire of Ferdinand Eisele GmbH from the Pforzheim area since 1987Back then, 10 years after the German launch of product identification by barcode, the impressive sum of DM 16,000 was invested in a thermal transfer printer to install an imprint service. Customers should be able to order the labels produced in-house ready printed with customised data and coding. In the meantime, barcode imprinting has been established as a much sought-after service. The company has extensive expertise in one-dimensional codes, the barcodes, in their various forms such as Code 128, 2/5-interleaved, Code 39 and others, but especially EAN-13.

More information with the second dimension

When GS1, the organisation for assigning the ‘European Article Numbering’ (EAN), now GTIN, authorised all manufacturers to label goods with new 2-dimensional codes, eXtra4 stays up to date. 2D codes, known as matrix codes, can encode more content than is possible with the 13 digits of EAN-13. In addition to the previously coded information on country of origin, manufacturer and item identification, this means additional content such as batch number, production and expiry date, the packaging unit and much more. Matrix codes, as a rectangular field usually squared, consisting of white and black pixels, prove to be space-saving and are known to everyone today in the form of QR codes for encrypting web addresses.

2D codes ideal for industry

With its compactness, 2-dimensional coding is particularly interesting for the jewellery, watch and gemstone industries. Matrix code fits easily onto the particularly small-format labels that are common there. It can also be extremely reduced in size without any loss of function, which leaves room for other data. Even when damaged, it remains fully readable with only 3/4 of the pixel image.

At Ferdinand Eisele, this code has therefore long been integrated into the product range, both in the imprint service and on the software side, in the programmes offered by the subsidiary ‘eXtra4 Software+Service’. They are able to generate corresponding matrix codes and output them on labels. ...